In an increasingly electrifying automotive world, the issue of battery cooling is becoming a hot-button issue. The temperature of an EV battery has tremendous bearing on how safe it is to charge it. Car makers advise their customers to allow the car batteries adequate time to cool down before they start charging. But, when you’re driving a distance on a schedule and you pull up after 150 miles in order to connect to a DC fast charging unit, you’re unlikely to take this into account.

How are EV Batteries Cooled? Liquid Vs. Air

EV batteries are a bit like a child that you need to take care of; you have to warm them up when they get cold, and cool them down when they get too warm. They don’t like any kind of extreme. The two preferred systems of cooling are air cooling and liquid cooling, but what is the difference between them?

Air Cooling:

This method works by using simple convection as a way of transferring heat away from the battery pack. Air runs across the surface of the hot battery, dragging away the heat emanating from it as it moves. Of the two cooling systems employed by EV makers, air cooling is the earlier because of its relative simplicity in both principle and practice. Air cooling has been employed by models such as the Nissan Leaf.

Liquid Cooling:

This method can also be further split into two types: direct and indirect. Direct liquid cooling involves submerging the battery into coolant, which means that the coolant itself has to be a non-conductive liquid. This format has great potential for the future, but safety concerns mean that it is still at the “drawing board” stage, currently.

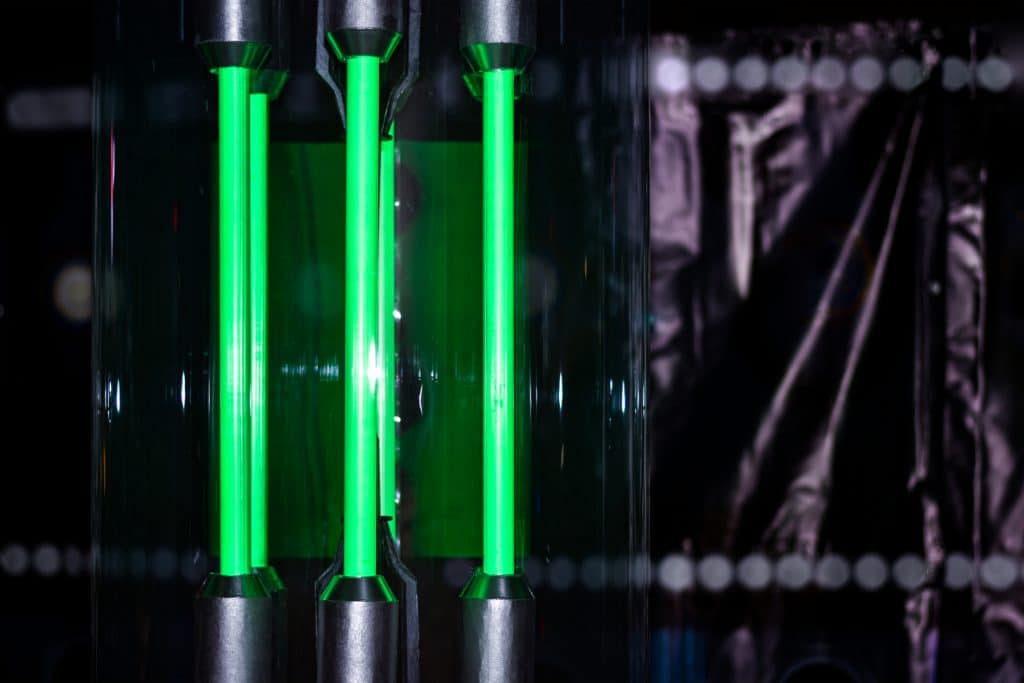

Indirect liquid cooling works by circulating coolant through pipes in a similar way that traditional car engines do. This means that the coolant needs to have a high heat tolerance and also not act as a corrosive substance at the same time.

Other Systems:

There have been alternatives to air and liquid cooling, including fan cooling and phase change materials. These, however, have proven impractical for various reasons, most importantly because they don’t align well with the design or performance of a typical electrical vehicle.

Among the many options for cooling systems, the most promising seems to be indirect liquid cooling. A direct cooling system would be even better, but it will take more time to allay the various safety concerns that still exist. This brings us, then, to the meat of today’s piece.

Which Electric Cars Have Liquid-Cooled Batteries?

As air cooling proves incapable of meeting the increasingly diverse demands for EV cooling, such as those of hot climates in countries like the UAE, as well as parts of China and the US, makers are now looking to liquid cooling as a lasting solution. The question is, which automakers are already making use of this technology in their production models? Today we will explore this.

Tesla

Elon Musk has been among the most actively vocal in support of liquid cooling systems, even going so far as to deride other car makers who are not making use of the technology. As early as 2010, he was claiming that companies like Nissan were making a huge mistake in employing air cooling. He even went so far as to call their design “primitive.” In tech circles, that’s about as insulting as it gets. Musk further pointed out that even Tesla’s earliest prototype made use of liquid-cooled batteries.

Tesla’s first need for an efficient and effective cooling system came about after their first designs for the Roadster began back in 2006. As the car accelerated to its limits, there were some serious thermal concerns with the battery, even creating serious fire risk that would mean the car would never be safe for production. The result of this problem was development of what we now know as the Tesla BMS (Battery Management System), and it has done nothing short of revolutionizing EV battery technology.

Tesla Model S

We’ll use the Model S as an example. It makes use of a pump-based coolant system that is actually quite similar in principle to that used by the Chevrolet Volt. Don’t be fooled, though, because Tesla’s system in practice is both unique and patented. Patent nerds may like to know that the application number was 20110212356. It can best be described as serpentine, and involves a cooling pipe that winds its way through the battery like a snake carrying coolant through it. The liquid used by Tesla is water-glycol coolant, which is different from that used by BMW, for instance (see more below).

The Model S’s battery requires an auxiliary water pump that can drive the coolant through the battery cooling circuit. The cooling system is made more efficient by the unique serpentine design described above, which allows for each battery cell in the pack to maintain full contact with the sides of the coolant tubes.

This is where Tesla sets itself apart. The result of this design is that cooling in the Tesla battery happens more evenly. This in turn helps ensure a better battery life, since most other EV batteries suffer due to uneven wear, which sends them into a state of imbalance from which they can rarely be recovered (unless they’re Toyota hybrid batteries, but that’s a topic for another day).

Companies like BMW have long expressed concerns over using coolant such as the glycol that Tesla is using. We have a bit more on that below. To allay those fears, however, and to prevent leaking of coolant from the system, Tesla designed their system to use a metallic inner tube. This massively increases the resilience of the system, and in particular makes it more resistant to impacts.

BMW

The BMW design differs quite greatly from that of Tesla. For their flagship i3 electric car, they rely on a system that is much more like that of an air conditioning unit. We’ll describe that in more detail below. In general, however, BMW does favor the use of liquid-cooled systems, but only those that don’t make use of potentially dangerous chemicals or other substances that could cause environmental damage or health risks if leaked out.

Since 2019, BMW has been seeking new solutions for EV battery cooling to meet the increasing needs of cooling speed. Charging is getting faster, but the cooling rate stays basically the same, if not diminishing over time.

BMW is therefore currently investing in research into thermoacoustic cooling, electrochemical cooling, absorption cooling and many other direct methods. The only thing that really unites them with Tesla is their apparent disdain for passive cooling technologies like air cooling.

BMW i3

The BMW i3 has a slightly different design on its liquid-cooled battery compared to that of Tesla. They make use of AC fluid, which means they don’t need the addition of a water pump. Using AC fluid means that the i3 doesn’t have to push coolant around, but simply makes use of the AC compressor. In fact, it means that the battery uses a lot less of it. The refrigerant is pushed through the cooling system that is installed on the bottom of the battery casing of the i3 battery.

What this particular design does mean, however, is that the AC compressor does need to be a bit more “heavy-duty” in order to meet the extra demand. It’s no longer just running the air conditioning system for the cabin, but now also for the battery pack, too. Surprisingly, however, this boost doesn’t have to be as dramatic as you might think.

Chevrolet

Chevy EVs have made use of some slightly different systems over time, one involving a “coolant loop” which in principle follows Tesla’s lead, but the later Bolt models use a bottom-mounted AC-style system more similar to BMW. The main difference, however, is in choice of coolant. We’ll look in more detail below:

Chevrolet Volt

The Volt was built with 4 separate cooling systems, each known as a “loop.” The one relevant to today’s article, of course, is the power electronics cooling system loop, which cools both the battery and the power inverter module. Thermal passages that passed in between the Li-ion cells allowed coolant to flow through the battery.

Chevrolet Bolt

The Chevy Bolt uses a bottom cooling plate that makes use of water-glycol mix as opposed to BMW using AC refrigerant.

Ford

Elon Musk and Tesla might think they are the original pioneers of this technology, and to be fair, their patent is a testament to that, but Ford were also early adopters of the liquid-cooling techniques. Ford said very early on in 2010 as they were preparing to release the Ford Focus Electric:

“Active liquid systems are more effective than air systems at regulating lithium-ion battery temperature.”

Ford, 2010

Ford Focus Electric

What’s quite interesting about the Ford Focus Electric’s cooling system is how they touted its cooling and heating properties and how they can work in conjunction with the charging process to maintain a proper temperature of the battery while charging. When connected to the power grid, the Focus Electric uses ambient temperature data to adjust the cooling/heating of the battery to ensure that it is always charging at the perfect temperature.

Jaguar

Jaguar has also been a keen proponent of liquid-cooled technology for their EV. Their flagship electric SUV, the I-PACE uses an innovative system that we’ll describe in more detail below. Where Ford focused more on the benefits of an active smart system to help prevent battery degradation, Jaguar are focusing more on what all this means in terms of the EV’s range. When range anxiety remains a top concern for yet-to-be-converted drivers, perhaps this is a smart move on Jaguar’s part. The company also calls upon its racing heritage to guide its cooling system design.

Jaguar I-PACE

The I-PACE is built with a sophisticated and comprehensive thermal management system that manages the temperatures of the battery, the electric motors and the driver/passenger cabin. The I-PACE actually takes heat generated by the electric motor, for example, and distributes that heat either to warm the battery when needed, or to warm the cabin, which thus reduces pressure on the battery and helps it to last longer.

As fun as thermals are, we are more interested in how the liquid cooling of the battery works within this management system. The I-PACE is built with a cooling plate water-cooling system, which is integrated right into its frame. There are six cooling plates in total, mounted together onto the base plate. Coolant begins at the front on the left-hand side before being pushed through the cooling plates and returning back to the front on the right-hand side.

The system remains off while the battery is within its optimal temperature range, but then activates automatically when straying outside of this.

Conclusion: To Liquify is Better than to Air

Despite the obvious advantages of air-cooling systems in terms of simplicity and overall cost, it does seem that they are not capable of meeting the increasing cooling needs of electric cars that are becoming increasingly more sophisticated and powerful. Liquid cooling allows for greater amounts of power to be pushed through the battery, since the capacity for preventing overheating or even fires is greatly increased.

Air just can’t keep up with that demand. If the early Nissan Leaf were determined to be the pinnacle of where electric vehicles could go, then an air-cooling system would be sufficient, but as it is, this isn’t the case, as Tesla are consistently proving with their new technologies.

Cost remains a significant issue, however. Let’s not forget that in many countries, the only thing that makes EVs affordable to buy for most people is the significant subsidy you can get from the government to purchase an electric car. Increasingly complex cooling systems might be an additional burden that slows or even hinders progress already made to create more downward pressure on the prices of electric cars in the marketplace.

Despite this, it’s obvious that we can’t continue to rely on air-cooling systems, so we should look to those companies who are leading the way in developing innovative and effective liquid cooling for our increasingly overheating EV batteries.

1 comment

[…] These Electric Cars Have Liquid Cooled Batteries … […]