The automotive world is increasingly electrifying, and there is no escaping this fact. Countries all over the world, as well as quite a few US states to date, are committing to the idea of stopping the sale of new gasoline and diesel cars in favor of the promotion of battery electric vehicles (BEVs), as well as the limited continuation of hybrid EVs (HEVs) and plug-in hybrids (PHEVs).

As governments make the change, the world’s biggest auto makers are starting to react. The shift to EVs has created a pretty stark issue when it comes to car repairs and maintenance, however, as highlighted by startling data from the UK-based Institute of the Motor Industry (IMI). Their findings from 2018 show that 97 percent of active auto mechanics are not qualified to work on electric cars.

In today’s blog, we’re exploring the implications of these facts and other questions related to EV maintenance and repair.

IMI: 97% of Mechanics ‘Not Qualified’ to Work on EVs

Just about every one of the world’s major car brands currently has an electric model that’s either on the market or that will be imminently available. Even the former gas guzzlers like GMC Hummer are getting in on the electrified action. It’s rather shocking, then, to hear that once the EV sector becomes dominant after the UK’s proposed ban on the sale of new gasoline and diesel cars — set to come into effect in 2030, and 2035 for hybrid cars — only 3 percent or so of mechanics will actually be qualified to maintain and repair the nation’s cars. At the time the IMI was publishing those numbers, the UK’s cut-off year for combustion-engine cars was actually set at 2040. It was subsequently brought forward to 2030 by Boris Johnson, meaning that any problems it implies are now more pronounced than ever.

The IMI information went on in more detail, pointing out that these 3 percent of mechanics are almost exclusively employed by manufacturer dealerships. If these numbers are to hold true even to half the degree that it is currently, then the EV owners of the future will have a very limited choice of service centers for their vehicles.

It’s also a pretty thorny issue for the country’s regulators and lawmakers. The main reason for this shortage will be traced back directly to the government’s own policy of limiting the production and sale of gasoline and diesel cars in favor of promoting EVs. It might be a great-sounding policy to cut CO2 emissions, improve the local environment and contribute to solving wider issues like global warming and climate change, but on a practical, everyday level there remain serious issues to be resolved.

It seems that Britain is not alone in its concerns over the apparent lack of qualified EV technicians. In the US, the Chicago Tribune interviewed auto mechanic Craig Van Batenburg, who told them in no uncertain terms, “People are freaking out,” further adding that “Ninety percent of our industry has done nothing – absolutely nothing – to prepare.” Van Batenburg claims that most auto shops are simply turning away hybrids and EVs. That works when they are still in a tiny minority of your customer base, but what happens when the EVs become the mainstream?

In the next section, we’ll look at some of the unique areas in which electric vehicle maintenance is different from that of combustion-engine vehicles.

What Makes EV Maintenance and Repair So Special?

1. Cutting out the minor maintenance

Perhaps the most immediately noticeable thing is how many fewer tasks there are to do because of the dramatically different makeup of an EV compared to a traditional gasoline car. Most auto shops build their businesses not on fixing cars after major accidents or anything like that, but rather on the “bread and butter” services that they can offer. These services include the most routine items in a car’s maintenance schedule:

- Oil change

- Filter changes: oil, air, fuel, etc.

- Transmission fluid change

- Brake fluid, coolant and other fluid changes

- Checking battery health

- Checking/replacement of hoses, belts, chains, gaskets, etc.

- Brake pads and rotors

- Emissions checks

- Tire maintenance, rotation and inflation

- …and the list goes on

Among these, how many apply to an electric vehicle? There’s no combustion engine and therefore no engine oil, no transmission fluid, no hoses, belts, chains or gaskets, no emissions…the list of parts that belong to a combustion engine but have no place in the powertrain or drivetrain of an EV is seemingly endless. For the user, it’s good news, because it means that you don’t need to take the car into the garage as often for routine maintenance. For the auto shop, however, this is obviously very bad news.

Take a popular EV like the Chevrolet Bolt, for instance. It too has a maintenance schedule and does still require an annual service, but the contents of this schedule are rather different. Whereas a regular car would need an oil change every 3,500 to 5,000 miles (possibly longer if they use synthetic oil), as well as filter changes and all the other things described above, the Bolt only requires:

- Tire rotation every 7,500 miles

- Cabin air filter replacement every 22,500 miles

- Coolant flushed every 150,000 miles

That’s the meat of the schedule right there. Now imagine these meager few tasks shared between the estimated 160,000 independent auto shops across the United States.

In the EV-guided future, with so much less work available for the thousands and thousands of auto shops, it follows that many will close down, unable to make ends meet with the dwindling demand for those “bread and butter” services that pay the bills and keep everyone in a salary.

2. Fewer moving parts

As we touched on above, the integrated electrical system of the electric vehicle is one that involves far fewer moving parts when compared to that of a combustion engine. The traditional gasoline-powered engine is an intricate network of cylinders, gaskets, belts, hoses and other interconnected parts. This linked network of components is the life-blood of the auto shop industry because when even one small thing goes wrong, it has a chain reaction that impacts more systems down the line. When you cut out these myriad components, you have a system that rarely needs the same kind of attention.

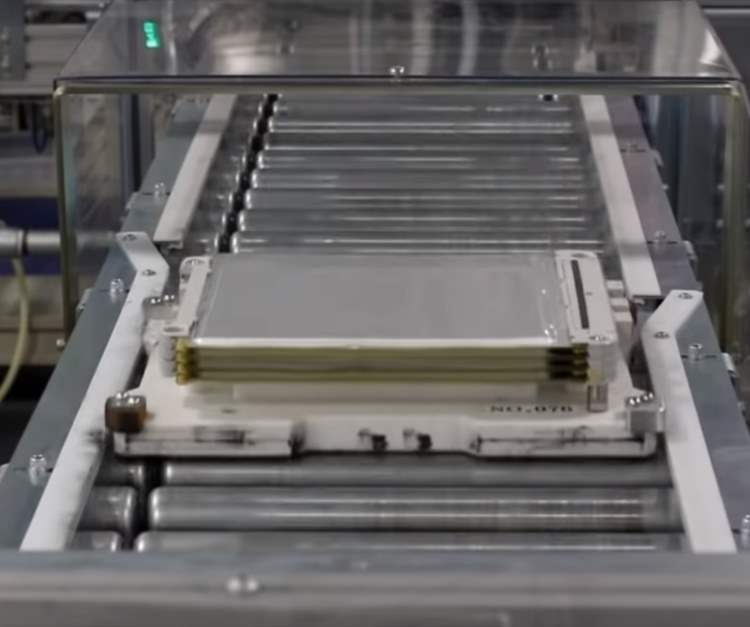

Most EV technicians are focused on the health of the main battery pack. Other electrical systems are important, of course, but everything that works within any EV does so on the basis of good overall battery health. It’s a lot more integrated and united as a system. Its maintenance, therefore, requires an entirely different skill set to that of the traditional mechanic, who has to diagnose specific component faults and then replace them to restore harmony to the machine.

3. OTA updates

Some EVs — most notably Tesla — make use of incredible over-the-air (OTA) updates that not only solve the software and firmware problems of the EV systems, but now can even be used to solve mechanical issues. First of all, the more heavily computerized nature of EVs makes them beyond the skill of many regular mechanics. While most mechanics have some understanding of computer-based automotive technology, the skills gap is increasing as more and more systems require programming skills and a deeper electrical knowledge to solve. Being armed with an OBD-II scanner and a knowledge of error codes won’t be enough for the EV-guided future.

The implication of this is that in the future, repairs and servicing will most likely be carried out remotely, with physical repairs and maintenance reduced to an absolute minimum. When OTA updates were focused entirely on the infotainment system and digital management of the car’s features, that was one thing, but when Tesla proved in 2018 that they could use an OTA update to fix braking in the Model 3, the world got to see the potential of the remote car servicing and repair industry.

Since Tesla paved the way for OTA updates to become the norm, other international OEM giants such as Ford and BMW have also started moving in the same direction. Once it is shown to work, the first domino has fallen.

4. Battery evolved

Another thing we touched on above is how the EV battery is now at the very heart of the operation. The skills and procedures involved in battery health and maintenance are so different from those skills already known by most auto mechanics. While all gasoline cars are also fitted with 12-volt batteries, these are but toys to when compared to the intricacies of the EV battery pack.

EV batteries are all about proper chemistry. A regular mechanic is qualified to service a 12-volt lead-acid battery. Those batteries are also relatively simple to replace should the time come. You can’t do the same thing with the core battery pack of an EV, however. It can be replaced and repaired, but the level of knowledge required, as well as the equipment, is totally different. These are things that unfortunately beyond the skill of the regular mechanic.

To become qualified for EV battery servicing, most ordinary mechanics would have to undergo training with the OEM technicians to learn about the different battery chemistry, balance in capacity between the cells, how and when to restore battery power balance, diagnosing problems in individual cells and more.

5. Regenerative Braking

Another big phenomenon in the EV world is regenerative braking. This concept first emerged in hybrid vehicles, but has since evolved into a mainstream technology heavily used and marketed, especially by Tesla and Nissan. This system allows the driver to slow and even bring the car to a complete stop simply by taking their foot off the gas pedal.

Don’t all cars do that? Well, yes, physics will always bring a car to a halt if you remove your foot from the gas pedal, but the question is how long would it take. The regenerative braking on a Tesla Model 3, for example, when set to “Standard” can bring the car to a halt almost as soon as if the driver were to regularly apply the brake.

What does this mean for mechanics? It means that even one of the few systems on an EV that they would be very familiar with, the brakes, is being used far less because of the reduced strain that comes with using regenerative braking. The system works by reversing the motion of the electric motors. When the technology improves further and is applied across all EVs — primarily as an energy-saving measure — then even the need for car brake repair is diminished.

6. Technician Safety

One final question when it comes to EVs is how safe a regular mechanic would be trying to effect repairs. Mechanics know about the dangers of electrical wiring and other components, of course, but when the entire car runs on electric power and there are hundreds of volts running through the system, there is clearly more training and finessed knowledge that is required.

Can Mechanics Retrain? What Will They Have to Learn?

Perhaps it’s unfair to characterize the current world of the mechanic as one of ossified pure mechanical practice in which only brute strength and analog parts mean anything. Talking to the Washington Post, Virginia-based auto garage owner Bill Moss pointed out even as early as 2017, “We already do a lot more work with a laptop than we do with a wrench anymore…Some of this is nothing new.” Moss began retraining his own employees in 2017 to work on electric cars.

Vice president of the Automotive Maintenance and Repair Association Jeffrey Cox is equally optimistic, reminding us that mechanics still have years to prepare, “The market share that they’re going to have will be small for the first five years and then it will be another five years before their warranties end they start being resold and needing work.”

The key to retraining is clearly based in IT skills. Cox remarked also when interviewed by the Washington Post that “the auto technician of the future will need to become some combination of your company’s IT support guy with a car-lover’s mind, someone with the ability to change tires and operate diagnostic and scanning equipment to root out problems involving computer networks and data processing.”

Therein lies the key. Mechanics will survive because in reality what they have to do is merely continue in an ongoing evolution to more digitalized solutions. It’s already the case that a mechanic today doesn’t need to take the same approach of seemingly endless inspection and trial and error as the old mechanics did. Since OBD-II scanners became the norm, most problems can be narrowed down to a single system or component in mere seconds.

Furthermore, training mechanics to support customers with their software-based trouble is much easier to do en masse than it is to train them in physical mechanical skills, which normally takes years of close apprenticeship. The information age can see mechanics learning from home computers and tablets the various skills they need to continue serving their clients.

Conclusion: Will the EV Revolution Kill the Humble Mechanic? Not Yet.

In the end, there’s undoubtedly going to be some pretty significant disruption within the auto shop sector sooner or later. When EVs do become the mainstream, the number of mechanics and auto shops as we currently understand them will certainly go down. This is because the realities of EV maintenance do dictate that there will be less work to go around. The maintenance schedule of the current Chevy Bolt proves that.

On the other hand, even in the UK where sales of new gasoline cars are to be stopped in 2030, that won’t cut off all internal-combustion-engine cars in 2030. It only bans the sales of new vehicles. There will certainly be a long period of continuation where drivers continue to drive their existing gasoline car, as well as purchasing used gasoline cars. It might take another 10 or 15 years for EVs to truly become the dominant force, by which time it is reasonable to assume that a new generation of emerging mechanics will fill the gaps.

Fewer mechanics? Certainly. The end of the auto shop trade? Not likely. The OEM dealerships will certainly dominate initially, but over time plucky entrepreneurs will find new and innovative ways to offer the same services for less, giving rise to a new kind of independent auto shop.

1 comment

And the qualified independents are priced out of buying the calibration equipment needed for the motors at service which currently run at £120,000 a unit which will take over two decades to be paid off unless they overcharge customers to claw back the investment. Its farcical when we know porsche will soon release a synthetic carbon neutral fuel, we don’t need electric